- Natural Stone

- Artificial Stone

How Are Granite Countertops Made?

Granite countertops are a popular choice for their natural beauty, durability, and timeless appeal. But have you ever wondered how these stunning countertops are made? Understanding the process can give you a greater appreciation for the craftsmanship involved. Let’s delve into the fascinating journey of how granite countertops come to be, from the quarry to your kitchen.

1. The Beginnings

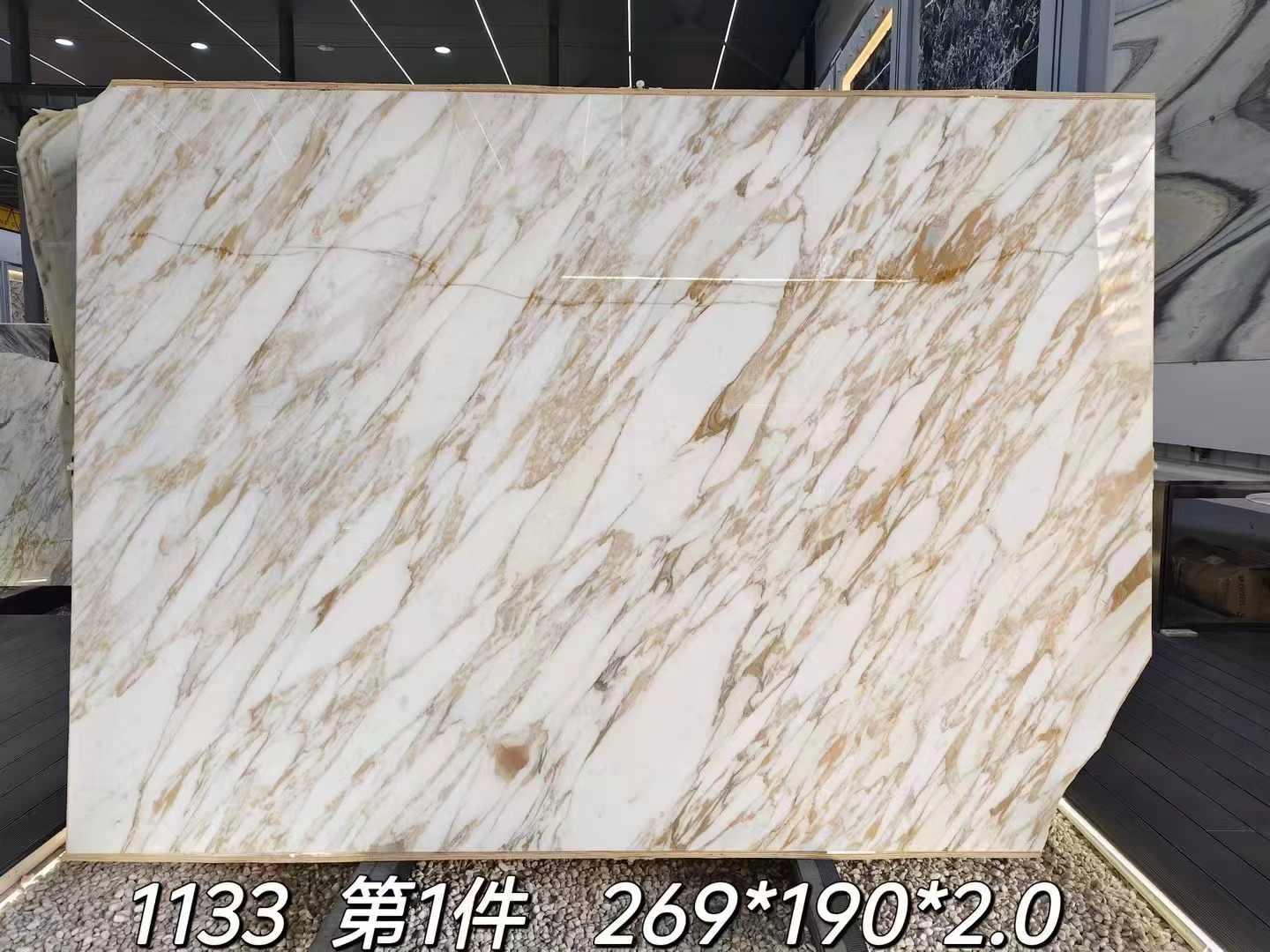

Granite is a natural stone known for its heat resistance and durability, making it one of the top choices for luxurious countertops. Its luminescent glow when polished comes from the locked crystals of minerals that make up the rock. Granite is primarily composed of quartz and feldspar, with other minerals contributing to its unique appearance.

Granite for countertops is sourced from quarries around the world. It is extracted using various methods, including blasting, drilling, or chiseling. Mining machines cut the granite into slabs, typically about five feet wide and nine feet long. Larger slabs can be more expensive. Specialized machines then polish these slabs to ensure an even thickness, giving the countertops their smooth finish.

2. Cutting

The next step in creating granite countertops is cutting the stone. Most of this process happens at the quarry, but some final shaping occurs on-site during installation. Cutting granite requires specialized equipment, such as a diamond cutting blade attached to a skill saw. Professionals often use collars on each side of the blade to reduce vibration and prevent chipping. Additionally, a vacuum attachment helps manage the dust created during the cutting process.

The edges of granite countertops can be shaped in various ways, such as beveled, flat, curved, or rounded, depending on your preference. Achieving perfectly matching edges and corners is challenging, so professionals use automated edge-shapers to polish and cut the edges precisely.

3. Installation Preparation

Once the granite slabs are cut and polished, they are ready for installation. This process requires careful planning and precise measuring. In the kitchen, appliances like the fridge and stove need to be removed to make room for the new countertops. The sink must also be taken out of the countertop. If the current countertop is attached with screws, you might need to remove the doors and drawers from the lower cabinets.

Installers will measure the openings for appliances to ensure a perfect fit. They will also consider the thickness of the backsplash to ensure the faucets will fit correctly. A template can help create the right amount of space for a cooktop or sink. Protect the subcounter with a layer of plastic sheeting to prevent damage during installation.

Seams are common in granite countertops because most slabs are under 10 feet long. While it’s possible to get longer pieces, they are much more expensive. If you prefer a seamless look, you might need to opt for a different material or accept the presence of at least one seam.

4. Installation

During installation, seams should be placed where the cabinetry is well-supported. If the two pieces of granite have slight differences in thickness, a shim can help ensure the counter remains flush. Installers will apply silicone between the slabs to accommodate contraction and expansion. They will also use epoxy to secure the granite in place. Visible seams can be camouflaged with colored resin that matches the granite, making them less noticeable. The same resin can be used to hide the caulking used to attach the counter and the backsplash.

5. Sealing

While granite countertops don’t require sealing, a sealant can help protect the stone from dirt and stains. Granite is naturally moisture-resistant but porous, so a sealant helps prevent liquids from penetrating and damaging the surface. Colored liquids can stain the granite if not sealed properly. Applying a new layer of sealant annually helps keep your countertops protected. However, the frequency of sealing can vary depending on the porosity of your granite.

Ready for New Kitchen Granite Countertops?

Granite countertops bring the natural beauty and durability of stone into your home. They are stylish, match any kitchen design, and offer a timeless appeal. If you’re ready to transform your kitchen with granite countertops, contact us today. We can guide you through the process and help you choose the perfect granite for your home.

Latest News

-

Vanity Tops are Bathroom Worktops (WC’s, Toilets, Bathrooms, Ensuites)

Vanity Tops are Bathroom Worktops (WC’s, Toilets, Bathrooms, Ensuites)Vanity Tops: The Perfect Bathroom Worktops for WC’s, Toilets, and Ensui...

-

Kitchen Splashbacks and Upstands For Wall Protection

Kitchen Splashbacks and Upstands For Wall ProtectionKitchen Splashbacks and Upstands: Wall Protection Kitchen splashbacks and ups...

-

The Five Quartzite Designs

The Five Quartzite DesignsThe Five Quartzite Designs Quartzite is a stunning natural stone that combine...

-

Stunning Works: Marble Slab Wall

Stunning Works: Marble Slab WallStunning Works: Marble Slab Walls Marble slab walls are the epitome of luxury...

-

Red Marble: Color And Design Combined

Red Marble: Color And Design CombinedRed Marble: Color And Design Combined Red marble is more than just a materia...

-

Travertine Countertops

Travertine CountertopsTravertine Countertops Travertine is a natural stone known for its earthy ton...

-

Marble Kitchen Island: Best Ideas & Inspirations

Marble Kitchen Island: Best Ideas & InspirationsMarble Kitchen Island: Best Ideas & Inspirations A marble kitchen island ...

-

The Pros and Cons of Natural Stone Floor Tiles

The Pros and Cons of Natural Stone Floor TilesThe Pros and Cons of Natural Stone Floor Tiles Natural stone floor tiles have...

-

5 Key Factors How to Tell If Good Quality Marble

5 Key Factors How to Tell If Good Quality Marble5 Key Factors How to Tell If Good Quality Marble Marble has long been a sym...

-

5 Most Beautiful Green Stone Countertops For 2025

5 Most Beautiful Green Stone Countertops For 2025Introduction: Why You Should Go Green Stone with Countertops? In 2025, green ...