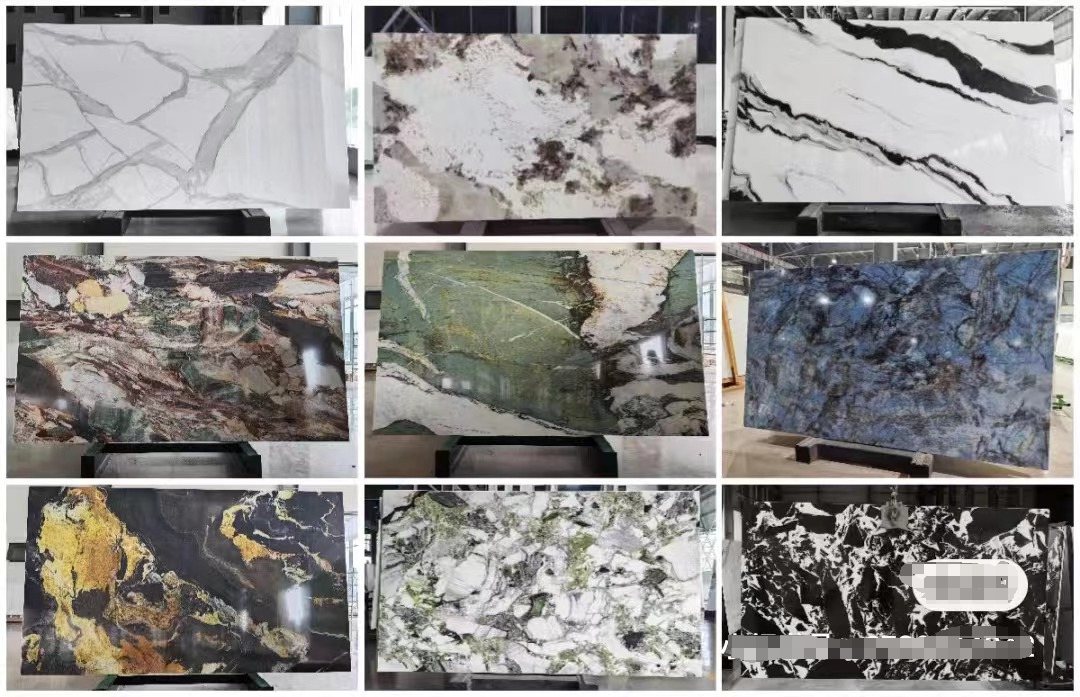

- Natural Stone

- Artificial Stone

The Complete Process of Crafting Marble Countertops: A Step-by-Step Guide

Marble countertops have long been synonymous with luxury and sophistication, gracing everything from ancient monuments to contemporary kitchens. Their natural beauty and timeless elegance make them a sought-after choice for homeowners. But how are these exquisite countertops created? This guide walks you through the intricate process, from extracting raw marble to installing the final product in your home.

A Brief History of Marble

Marble has been a cornerstone of architecture and design for millennia. One of the most iconic examples is the Temple of Artemis, constructed in 550 BCE, which boasted 127 towering marble columns. Though the temple no longer stands, its legacy underscores marble’s enduring allure and versatility.

The Journey of Marble Countertops: From Quarry to Kitchen

Creating marble countertops is a meticulous process that combines traditional craftsmanship with modern technology. Here’s a detailed look at each step:

1. Measuring and Templating

The process begins with precise measurements of the countertop space. Technicians create a digital template to ensure the marble slabs will fit perfectly. This template is then fed into a computer program, which guides the cutting and shaping of the marble.

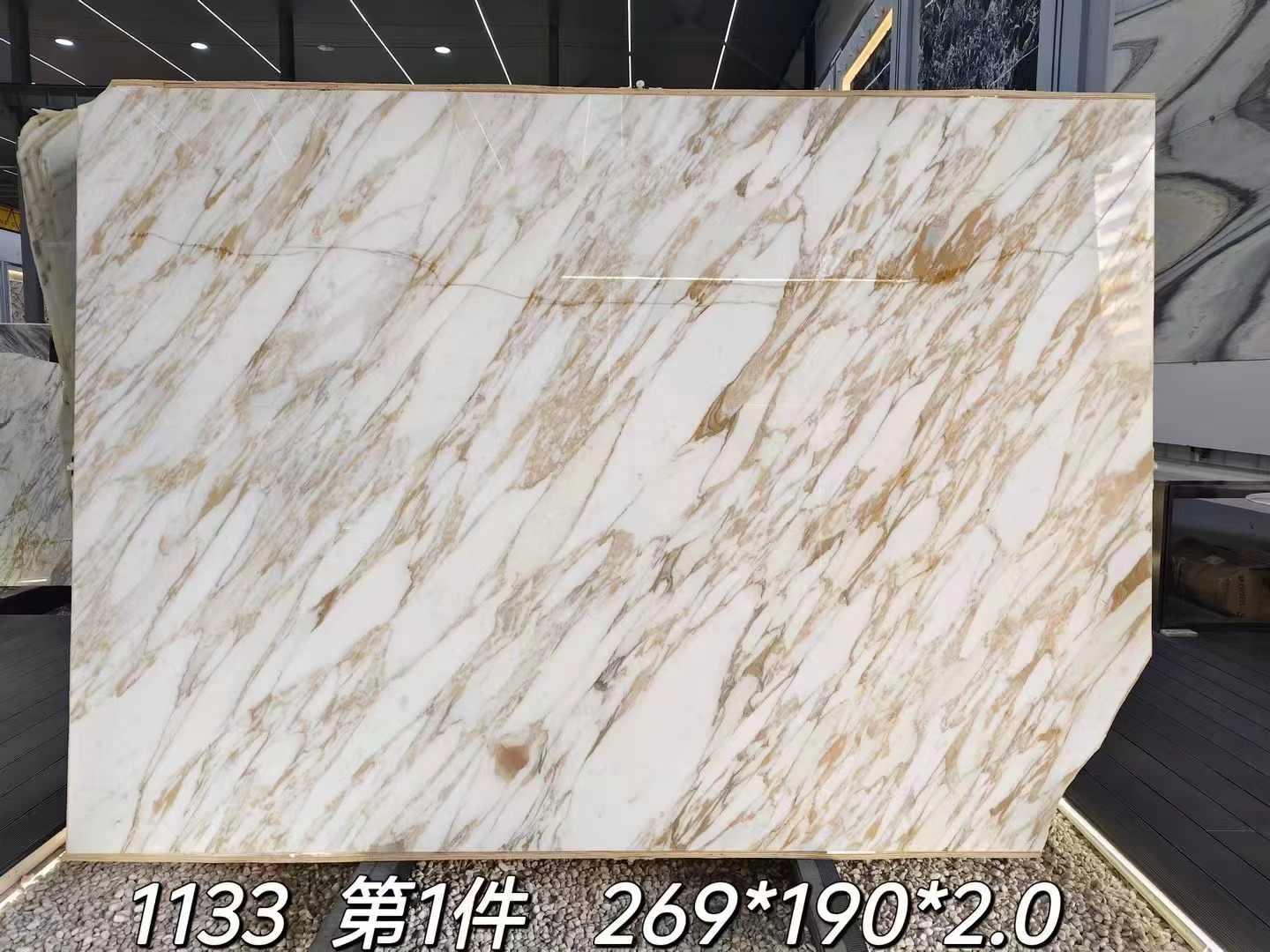

2. Quarrying and Transporting Raw Marble

Marble is extracted from quarries in large blocks using specialized equipment. These blocks are carefully loaded onto trucks, often cushioned with rubber foam to prevent damage during transit. Given marble’s high value, every precaution is taken to minimize waste and ensure the slabs arrive intact at the fabrication facility.

3. Cutting and Shaping the Slabs

Once at the fabrication shop, the marble blocks are cut into slabs using advanced machinery. A block saw or gang saw, guided by computer programs, slices the marble to the desired thickness. The slabs are then transferred to a CNC machine for further precision cutting, ensuring they match the template dimensions.

4. Water-Blasting for Smoothness

After cutting, the marble slabs undergo a water-blasting process. High-pressure water jets, exceeding 200 miles per hour and 70 pounds per square inch, smooth the edges and surfaces. This step prepares the marble for polishing and ensures a flawless finish.

5. Polishing and Detailing

The slabs are then polished using rotating pads with varying grit levels. Coarse sandpaper is used initially, with finer grits applied progressively to achieve the desired finish. Polishing can range from a high-gloss, mirror-like shine to a softer, matte appearance. Decorative finishes, such as hammered or flamed textures, can also be added at this stage.

6. Edge Profiling and Final Touches

Diamond-covered routers are used to shape the edges of the countertops. Water cools the blades during cutting, ensuring precision and preventing damage. Depending on the design, edges can be simple and straight or intricately detailed with decorative patterns.

Modern Machinery in Marble Fabrication

While the fundamental process of crafting marble countertops has remained unchanged for centuries, advancements in technology have revolutionized the tools used:

- Saws: Block saws and bridge saws cut marble blocks into slabs and shape them into countertops. Water jets and abrasives ensure clean, precise cuts.

- Polishers: These machines use rotating pads to achieve various finishes, from high-gloss to matte, and can even add decorative textures.

- Routers: Diamond-tipped routers create precise edge profiles, from simple bevels to intricate designs.

Installation and Care

Once fabricated, the marble countertops are transported to the installation site. Professional installers ensure a perfect fit, securing the slabs in place with adhesive and sealing the surface to protect against stains and scratches. Proper maintenance, including regular sealing and gentle cleaning, will preserve the marble’s beauty for years to come.

Choosing the Right Fabricator

Selecting a skilled countertop fabricator is crucial for achieving the desired results. Look for a company with a proven track record, state-of-the-art equipment, and a commitment to quality. A reputable fabricator will ensure your marble countertops are not only stunning but also durable and functional.

Conclusion

Marble countertops are a testament to the perfect blend of nature’s artistry and human craftsmanship. From quarrying raw stone to the final polish, each step in the process is designed to highlight marble’s natural beauty while ensuring its practicality for everyday use. By understanding the journey behind these luxurious surfaces, you can make an informed decision and enjoy a timeless addition to your home.

Latest News

-

Vanity Tops are Bathroom Worktops (WC’s, Toilets, Bathrooms, Ensuites)

Vanity Tops are Bathroom Worktops (WC’s, Toilets, Bathrooms, Ensuites)Vanity Tops: The Perfect Bathroom Worktops for WC’s, Toilets, and Ensui...

-

Kitchen Splashbacks and Upstands For Wall Protection

Kitchen Splashbacks and Upstands For Wall ProtectionKitchen Splashbacks and Upstands: Wall Protection Kitchen splashbacks and ups...

-

The Five Quartzite Designs

The Five Quartzite DesignsThe Five Quartzite Designs Quartzite is a stunning natural stone that combine...

-

Stunning Works: Marble Slab Wall

Stunning Works: Marble Slab WallStunning Works: Marble Slab Walls Marble slab walls are the epitome of luxury...

-

Red Marble: Color And Design Combined

Red Marble: Color And Design CombinedRed Marble: Color And Design Combined Red marble is more than just a materia...

-

Travertine Countertops

Travertine CountertopsTravertine Countertops Travertine is a natural stone known for its earthy ton...

-

Marble Kitchen Island: Best Ideas & Inspirations

Marble Kitchen Island: Best Ideas & InspirationsMarble Kitchen Island: Best Ideas & Inspirations A marble kitchen island ...

-

The Pros and Cons of Natural Stone Floor Tiles

The Pros and Cons of Natural Stone Floor TilesThe Pros and Cons of Natural Stone Floor Tiles Natural stone floor tiles have...

-

5 Key Factors How to Tell If Good Quality Marble

5 Key Factors How to Tell If Good Quality Marble5 Key Factors How to Tell If Good Quality Marble Marble has long been a sym...

-

5 Most Beautiful Green Stone Countertops For 2025

5 Most Beautiful Green Stone Countertops For 2025Introduction: Why You Should Go Green Stone with Countertops? In 2025, green ...